-

-

Product

-

-

-

-

How to Build a Sunshine Board Canopy

Release time:

2023-06-12

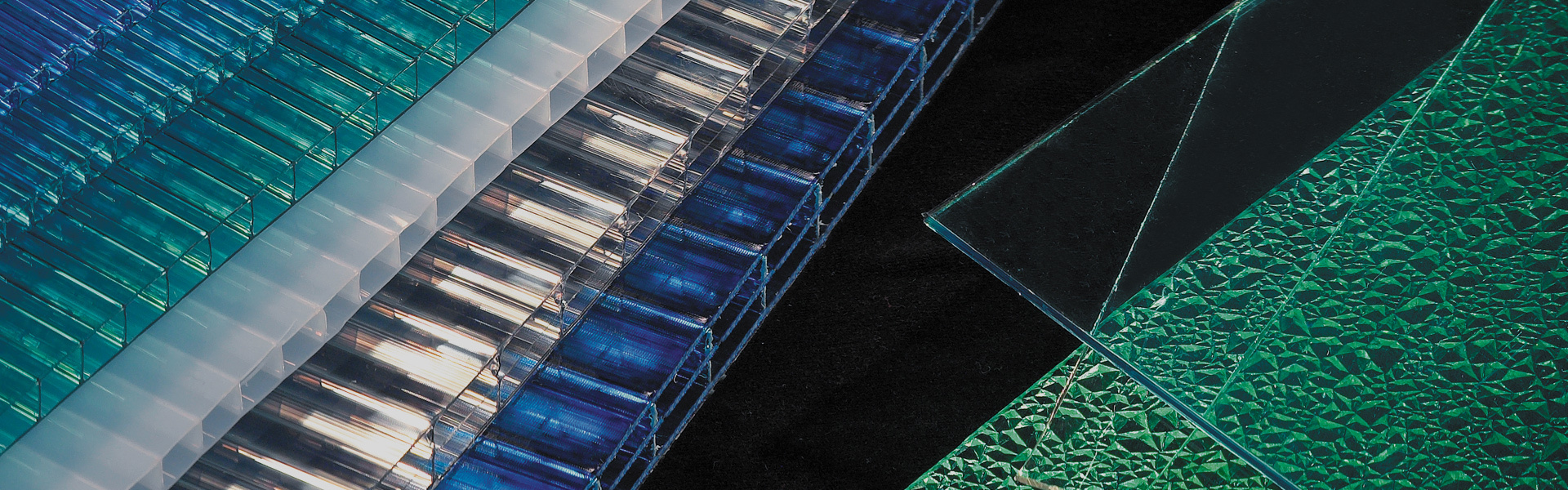

Sunshine board awnings are very common in our daily lives, because they can be seen everywhere, whether in underground passages or parking lots. Next, the editor of Decoration Home will introduce to you the relevant knowledge about sunshine board awnings. First, let's take a look at how to build a sunshine board awning.

Sunshine board awnings are very common in our daily lives, because they can be seen everywhere, whether in underground passages or parking lots. Next, the editor of Decoration Home will introduce to you the relevant knowledge about sunshine board awnings. First, let's take a look at how to build a sunshine board awning.

1、 How to Build a Sunshine Board Canopy

1. When building a canopy, the first thing we need to do is to check the skeleton. The skeleton must be flat and free from welding scars or burrs. The skeleton must be thoroughly dried and free from volatile solvents.

2. Then what we need to do is lay the butyl waterproof tape on both sides of the skeleton to form a small sink.

3. Place the sunshine board on the skeleton, and Expansion joint must be reserved between the boards.

4. Next, it's time to press the EPDM strip at the interface between the boards.

5. After completing the above steps, it should be fixed with self drilling screws.

6. What we need to remember is that the frame must be fixed at 1.05M in the middle of the width of the sunlight board, using self drilling screws to wrap the buttons.

7. The sunlight board against the wall should not come into direct contact with the wall. It should be fixed on the wall with angle aluminum, and then the sunlight board should be inserted and installed.

8. Seal the opening of the sunlight board with aluminum tape first, and then fix the edge strip or angle aluminum.

9. Then we should first check whether the cutting size and expansion allowance of the board are suitable, and pay attention to leaving sufficient and uniform expansion gaps. The calculation formula is as follows: total expansion gap=expansion coefficient * the length of the board with a larger temperature before and after installation in the local area.

10. Next, the most important thing remains, which is the installation project of hollow plates. The part of the middle plate that is clamped by the shaped plate must contain at least one rib, or the part of the plate edge that is clamped is smaller than 20MM. Identify the UV resistant side of the board surface and install it facing outward. It is absolutely not allowed to install the UV resistant side facing inward, which is something we must remember.

Zhongshan Goodlife Sun Sheet Co., Ltd

+86 760-23132001

Sales hotline:

+86 760-23132001

+86 13420298302 Candice Zeng

E-mail:joyce@goodlife.com.cn

Address:No. 8 Yifu Road, Nantou Town, Zhongshan City, Guangdong Province