-

-

Product

-

-

-

-

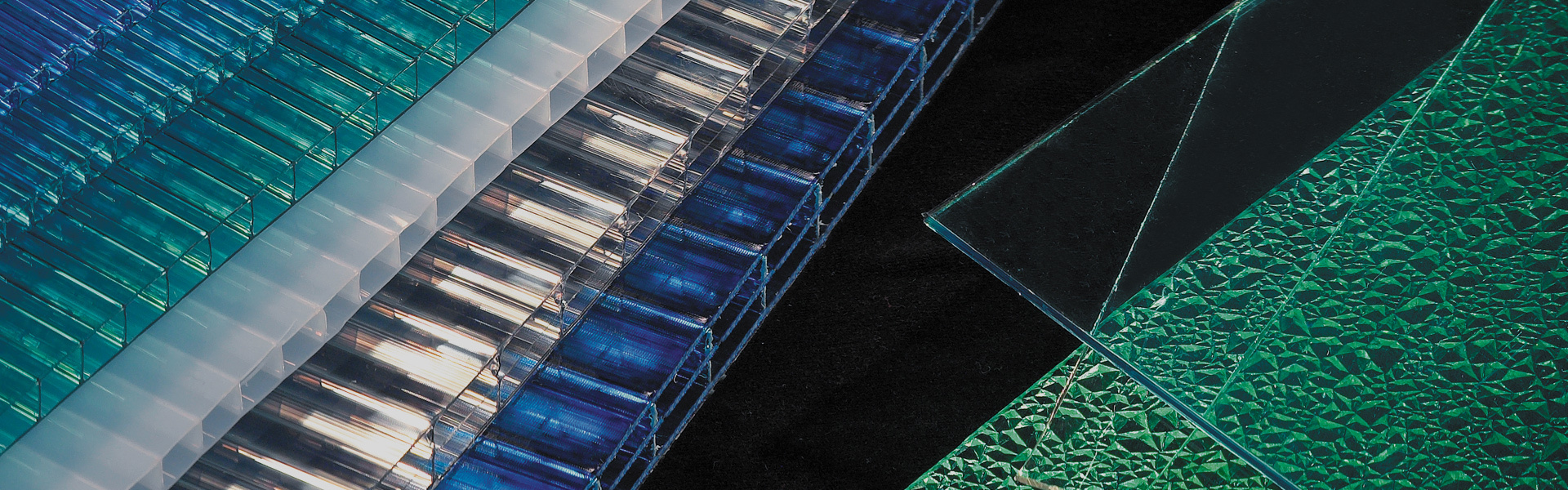

The primary construction process of hollow slabs

Release time:

2023-06-25

The primary construction process of hollow board 1. Snap line: Based on the elevation of the drawing, the orientation scale of the sunlight board ceiling, and the measured centerline, snap the main skeleton orientation line of the hollow board ceiling.

The primary construction process of hollow board

1. Snap line: Based on the elevation of the drawing, the orientation scale of the sunlight board ceiling, and the measured centerline, snap the main skeleton orientation line of the hollow board ceiling.

2. Embedded parts: Based on the elevation control line, check the orientation of the main skeleton of the hollow board ceiling to see if the exterior elevation of the opening counter beam meets the planning requirements. If there are differences, they should be chiseled or leveled with high-strength cement mortar. After reaching the strength, the direction line of the expansion bolt should be set out according to the scale of the embedded steel plate in the detailed plan node, and then the expansion bolt should be drilled and installed, and the steel plate and expansion bolt should be fixed. Then cast the centerline of the main skeleton onto the embedded steel plate.

3. Hollow board device main framework: According to the orientation line of the hollow board ceiling main framework, first install the two ends and then the center. The method is to add 60mm × 60mm × After the main framework of 3mm square steel pipe (galvanized) is assembled on the roof, it is manually placed on the orientation line, suspended vertically with a plumb line, and the center is temporarily fixed before welding with the embedded steel plate. After the two main frames are installed, pull the center and three longitudinal lines with a height of 1500mm on both sides (measured from the supports at both ends of the steel plate), and then install them one by one from one end to the other until all are completed.

4. Device secondary skeleton: After the main skeleton device of the hollow board ceiling is fixed, the hollow board ceiling of the device is 60mm × 60mm × 3mm square steel secondary skeleton, and adjust the orientation accurately. After leveling, weld and fix it with the main skeleton. Place moisture-proof agent together with the hollow board of the device.

5. Outer hollow board of the device: According to the layout direction of the deepening plan, prepare a 20mm thick sunlight board with suitable dimensions for the device installation

Zhongshan Goodlife Sun Sheet Co., Ltd

+86 760-23132001

Sales hotline:

+86 760-23132001

+86 13420298302 Candice Zeng

E-mail:joyce@goodlife.com.cn

Address:No. 8 Yifu Road, Nantou Town, Zhongshan City, Guangdong Province